wire edm machine working principle

No actual contact is made between the. What makes this special is that it can cut without contact and produces a.

Wire Electrical Discharge Machining An Overview Sciencedirect Topics

EDM stands for electric discharge machining.

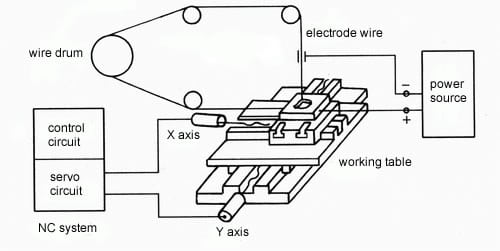

. Usually the work piece and wire are submerged in deionized water. Instead the metal material is gradually eroded by the pulse spark discharge generated between. CNC wire cut EDM machine puts impulse voltage between electrode wire and workpiece through impulse source controlled by servo system to get a certain gap and realize impulse discharging in the working liquid between electrode wire and workpiece.

A metallic wire usually brass or copper has high voltage electrical discharges passed through it that allows it to cut through the entire thickness of the material. The working principle of wire EDM machining is a process of separating metal materials by melting after the heat generated by electric spark discharge reaches the. No actual contact is made between the wire and the material which prevents distorting the path of the wire or damaging the part.

As mentioned earlier the EDM process does not require mechanical force. Principle of wire cut EDM. Working Principle of Electrical Discharge Machining Process.

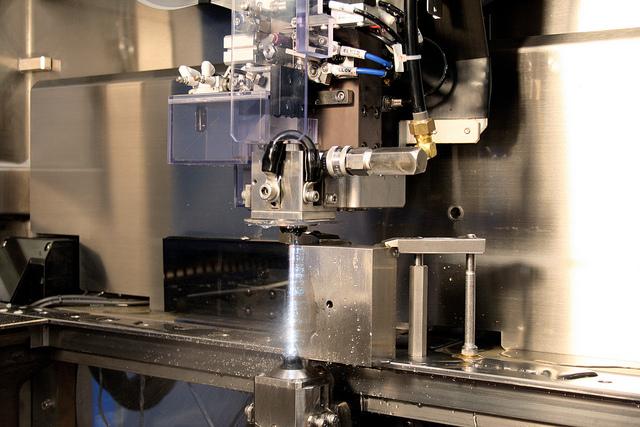

Wire EDM machines can make different shapes such as contours and holes even on the hardest and the most fragile materials. The Five Benefits of Using a Wire EDM. A wire EDM machine works in a similar way to a cheese cutter or a bandsaw cutting wood although the wire moves rather than the workpiece.

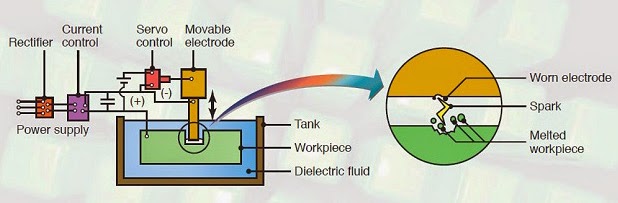

Electrical discharge machining EDM is a process of removing material by exposing it to repetitive controlled electrical discharges. This form of machining can cut any material that will conduct electricity whether it is a hard or soft material. The water acts as a dielectric electrical insulator until the electrical discharge happens.

Due to the inherent properties of the process Wire EDM can easily machine complex parts and precision components out of hard conductive materials. An electrical potential is generated between the. The difference between electrical discharge machining and general machining is that the tool and workpiece are not in contact during electrical discharge machining.

To simply put EDM involves removing excess material from a workpiece with the use of thermal energy. The electrode tool Cathode in the machine is connected to the negative terminal and the work-piece anode to the positive terminal of the DC power supply DC Pulse Generator. Wire EDM in process Wire EDM machine.

Wire EDM uses a thin wire composed of copper or brass to conduct electrical current between an electrical source and an electrically conductive base material. Electrical discharge machining EDM is a new technology that uses electric energy and heat energy to process. The use of precisely focused electrical discharges makes it possible to make complex or intricate shapes and patterns.

Makino EDMs have a streamlined and efficient interface that helps work get done faster. Wire EDM Tooling system is also known as wire cutting its basic working principle is the use of continuous moving electrode wire the workpiece cutting molding. Numerous tiny holes appears due to erosion of impulse.

Usually they are non-ferrous and include steel titanium. Wire EDM also known as Wire-Cut EDM works in a very similar way using a rapidly charged conductive metal wire to melt the material. When a discharge occurs between the electrodewire and the workpiece heat energy is generated on the workpiece.

As the spark jumps across the gap material is then removed from the work piece and the electrode. As the spark jumps across the gap material is. Wire filters and other consumables used on wire EDM machines.

WEDM process is based on the conventional EDM sparking phenomenon utilizing the widely. Used for die sinking or die manufacturing. Sparks jump the gap and melt away excess metal.

The Spark Theory on a wire EDM is basically the same as that of the vertical EDM process. Here are some applications of Electrical Discharge Machining. Wire electrical discharge machining WEDM is an advanced thermal machining process capable of accurately machining parts with complicated shapes especially for the parts that are very difficult to be machined by traditional machining processes.

It Doesnt Need Mechanical Force. It is suitable for thermoelectric phenomena. Wire EDM which came into commercial use in the 1960s uses a wire stretched taut as the electrode.

Wire electrical discharge machining EDM is a process of metal machining in which a tool discharges thousands of sparks to a metal workpiece. Wire EDM is a form of machining which is done using a thin wire that can cut in any XYUV direction. Wire EDM machining works by creating an electrical discharge between the wire or the electrode and the work piece.

Electrical Discharge Machining Working Principle What is the basic principle of EDM and how the material is removed in this process. A non-conventional process though hardly a new one wire EDM works on parts resistant to conventional machining processes but only if these parts are electrically conductive. A wire EDM machine can.

It is used for producing hole size less than 01 mm. This fabrication process ensures that engineers arrive at desired shapes only with the use of electrical discharges. Wire edm machine working principle.

The working principle of wire EDM machining is a process of separating metal materials by melting after the heat generated by electric spark discharge reaches the melting point of metal materials. It is not the most popular CNC machining. Wire EDM machining works by creating an electrical discharge between the wire or the electrode and the work piece.

Wire EDM machining works by creating an electrical discharge between the wire or the electrode and the work piece. It was invented by the former Soviet Union in the last century but China applied this technology to industrial production for the first time. Holes in the air brakes or Pneumatic Brakes were done by an electrical discharge machining process.

How Does Wire Cutting Work Dienamics

Production Technology Of Agril Machinery Lesson 7 Electrical Discharge Machining Edm

What Is Electrical Discharge Machining Edm Process And How It Works Mechanical Booster

Principle Of Wire Cut Edm 1 Download Scientific Diagram

Principle Of Wire Cut Edm 1 Download Scientific Diagram

Wire Cut Edm Process 2 Download Scientific Diagram

Review On Wire Electrical Discharge Machining Wedm Of Aluminum Matrix Composites Semantic Scholar

Working Principle Of Wedm Download Scientific Diagram

Wire Edm Find Suppliers Processes Material

Electrical Discharge Machining Principle Working Equipment S Advantages And Disadvantages With Diagram Mech4study

Eds Advantages Comparing To Wedm Tech Edm Trade Co Ltd

Mas 865 How To Make Something That Makes Almost Anything

Wire Edm Find Suppliers Processes Material

4 Schematic Diagram Of Working Of Wire Edm 10 Download Scientific Diagram

Wire Cut Electro Discharge Machining Process Working Animation Video Explained With Setup Diagram Youtube